How a beverage company achieved 19% annual cost savings from optimizing maintenance on bottle filler machine.

This beverage company produces and bottles carton upon carton of bottled drinks every day. Reaching the daily quota is imperative to keep retailers happy - and to keep the company in the black.

The Problem

Recently, the beverage company had been experiencing issues with one of its bottle filler machines. The result was lost downtime and liters of wasted juice.

To fix the costly problem, ARMS Reliability was engaged to perform a Reliability Centered Maintenance (RCM) study. The resulting optimized maintenance strategies reduced costs by 19%.

The Solution

ARMS Reliability recommended building a Reliability Centered Maintenance (RCM) model.

Equipment data, and current maintenance strategies and tasks were collated and a Failure Modes Effects and Criticality Analysis (FMECA) was performed in which all the likely and dominant failure modes were identified. Then, the consequences of each failure were added, in line with the company's corporate risk matrix.

Next, the current maintenance practices were captured in the model so an 'as is' simulation of the maintenance strategy could be run for comparison.

The model was then used to simulate the behavior of the machine over its lifetime to determine the impact of the maintenance tasks on the equipment lifecycle costs and risk levels.

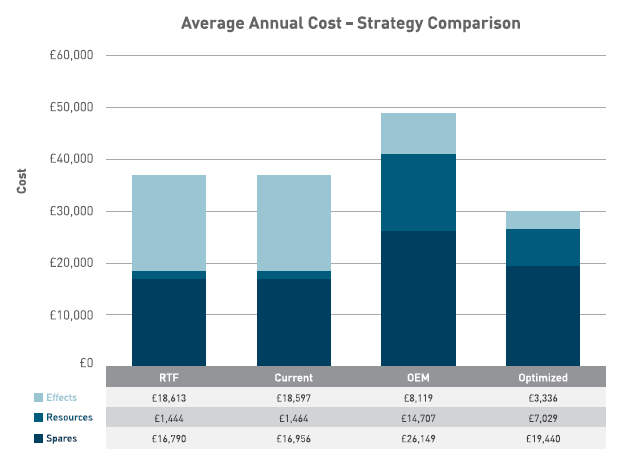

Four different scenarios were investigated: Run to Fail (no maintenance), Current Practice, OEM Recommendations and Optimized. The results were then compared.

Benefits of the RCM Study

The RCM study delivered these benefits for the company:

The Outcome

Armed with the results of the study, the company can now confidently execute the appropriate maintenance tasks on the bottle filler machine, knowing that the maintenance plan has been designed to ensure safe, reliable and economical use of the machine throughout its life.

With 11 failure modes identified as areas for redesign, root cause analysis or investigation, the company can also take a proactive approach - with further opportunities for reliability improvements and risk reduction. Above all, it's the bottom line that benefits. The company now uses an optimized maintenance strategy that has reduced the average annual costs by 19% compared to current practice.

Questions? We’ll put you on the right path.

Ask about our Maintenance Strategy Optimization services and technical solutions. We are ready to help.

Contact Us